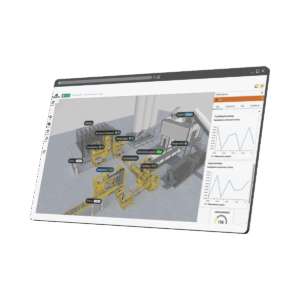

“What would you do if you saw everything in your factory in real-time?”

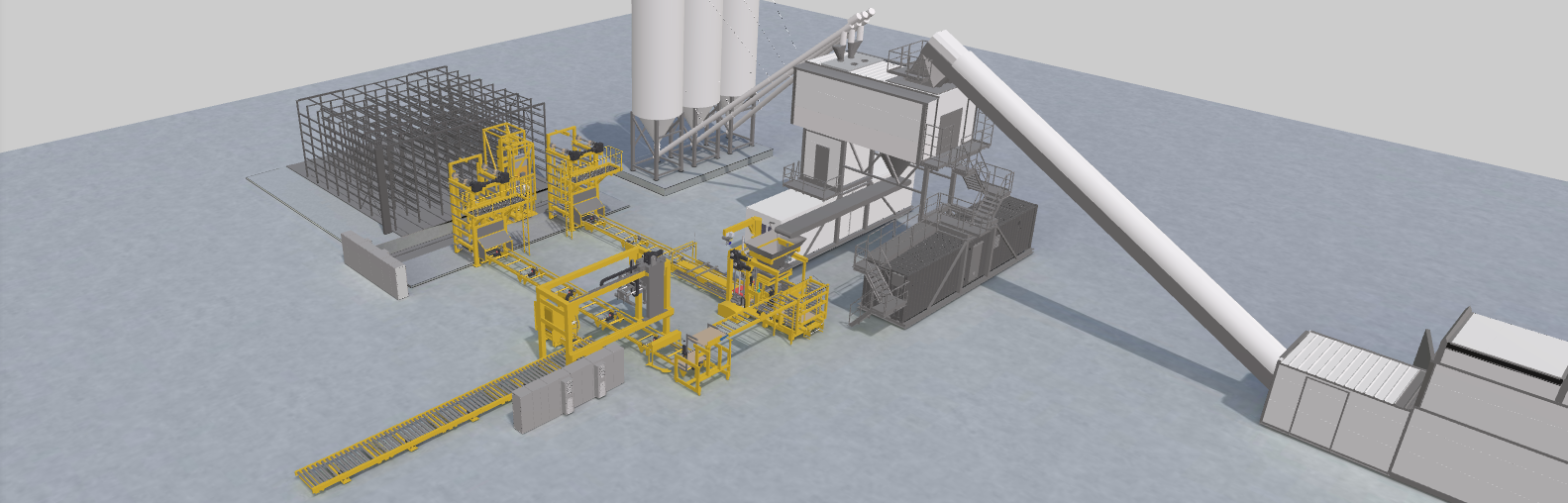

MEC Pro Factory

MEC Pro Factory is a Digital Twin of your concrete block plant — a real-time, virtual representation of your machines, processes, and data. It collects and transforms scattered information from across every system into one clear, centralized view, helping you visualize the entire plant, analyze production, and improve operations.

From production efficiency to maintenance, safety, and reporting, MEC Pro Factory makes your factory more transparent, more organized, and easier to manage, whether you’re on-site or home office.

What is a Digital Twin?

A Digital Twin is a virtual replica of a physical object, system, or process that mirrors its real-world behavior using real-time data. It allows companies to simulate, monitor, and optimize their operations without directly interfering with the physical version.

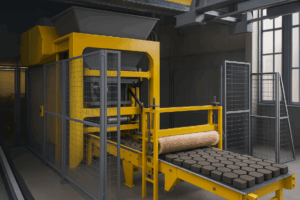

For example, in manufacturing, a digital twin of a concrete block factory can display live operating conditions, simulate changes in materials or machine settings, and predict maintenance needs before issues arise. This technology is particularly valuable for improving performance, reducing downtime, training staff safely, decrease reporting hassle and supporting data-driven decision-making.

Digital twins are commonly used in industries such as smart manufacturing, construction, energy, transportation, and even healthcare, playing a key role in modern digital transformation and Industry 4.0 strategies.

Why MEC Pro Factory?

- MEC Pro Factory gives you a clear, real-time overview of all the key data you need — in one place.

- Combines essential information from multiple data sources into a single, real-time dashboard — with historical context.

- Enhances monitoring by displaying only the most relevant insights based on each user’s role.

- Reduces the need for separate tracking and reporting tools.

- Minimal startup cost and no production stoppages required.

- Cost efficient based on number of data sources.

What MEC Pro Factory can offer?

- Machine manuals

- Maintenance log

- Real-time on/off/idle monitor

- Production efficiency charts

- Production volume charts

- Quality control

- Reporting tools

- Historical data

- Safety instructions and visual guidance

- Area restrictions and escape routes

- Location of first-aid kits and safety equipment

- Error/failure notification via email or phone

- Error/failure reporting tools and history log

- Water and electricity consumption

- Multi-location worldwide