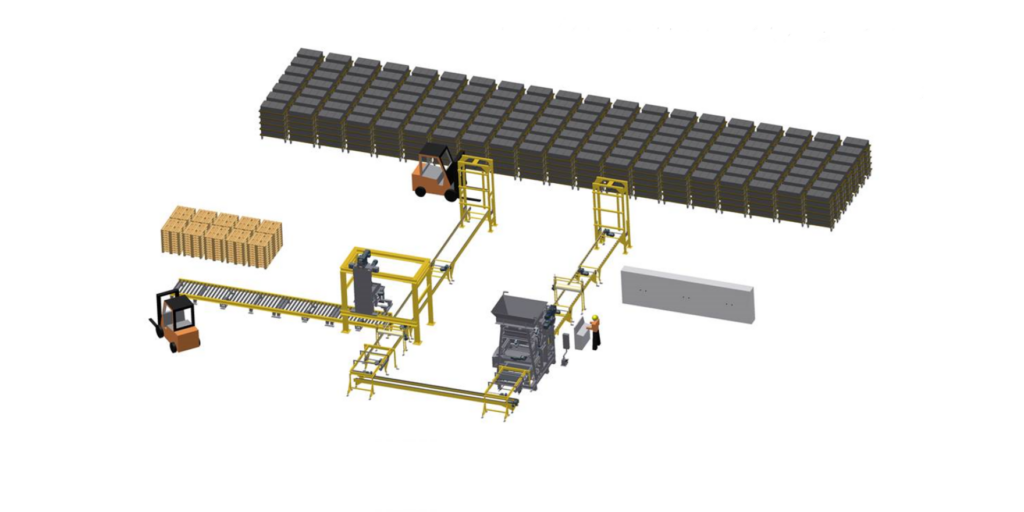

MEC STACKER concrete block production line includes fully automatic MEC block machine, semi automatic handling system with elevator and lowerator, fully automatic cured product packing line with production pallet returner.

What is MEC STACKER and how does it works?

The MEC STACKER is a semi-automatic concrete block production line designed for producing and handling masonry blocks, landscaping products, and various other concrete products with small to medium production volumes. This production line encompasses all stages of a block plant, from block forming to cured product packaging, excluding the batching plant. The name “MEC STACKER” is derived from its product handling system, where production pallets are stacked on top of each other in the curing chamber.

Handling and packing line operative principles

The production pallets containing freshly molded products are stacked automatically by elevator. These bundles, typically consisting of 3 to 5 production pallets, are then moved by a forklift to the curing area. After curing, the same bundles are transferred to a lowerator, which feeds the production pallets one by one into the packing machine. The packing machine stacks the products into the desired bundles, which are then either wrapped or strapped for storage or shipping.

When to consider MEC STACKER?

MEC STACKER is an ideal solution when there is insufficient space to install a CRANE or FINGER CAR handling system, yet fully automated block production and packaging operations are still desired. It is also more cost-effective for production that targets small to medium production volumes, typically handling 500 to 2,000 production pallets per day.

In many cases, the products manufactured using the STACKER line are more complex than traditional pavers or cement blocks. Due to this complexity, these products typically require a longer cycle time (20-35 seconds) for the block machine to produce them correctly, ensuring the highest quality and durability. As a result, the total production volume is lower, and the required handling capacity is reduced. The extended cycle time is essential to achieve the precision and structural integrity needed for these intricate or specialized products.

See also: Used MEC Stacker 1280