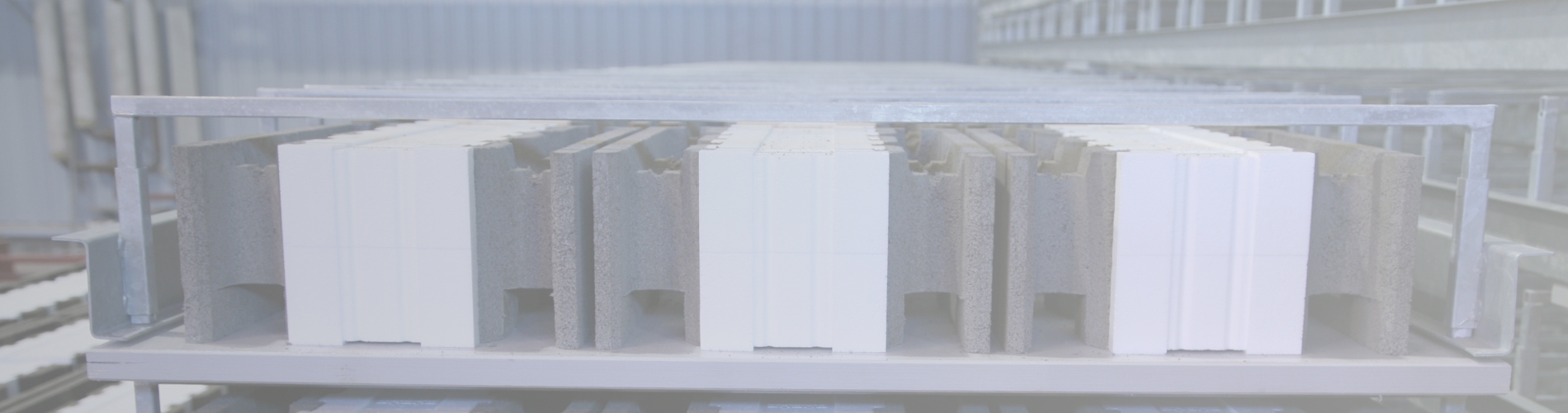

In the insulated concrete block machine model, the MEC Evolution-20 block machine is equipped with a fully automatic MEC insulation feeder, allowing for the fully automated production of insulated concrete blocks. Also known as thermal concrete blocks, these blocks are designed for high-quality living and offer several benefits, including very low thermal conductivity, fireproof, and fast construction times.

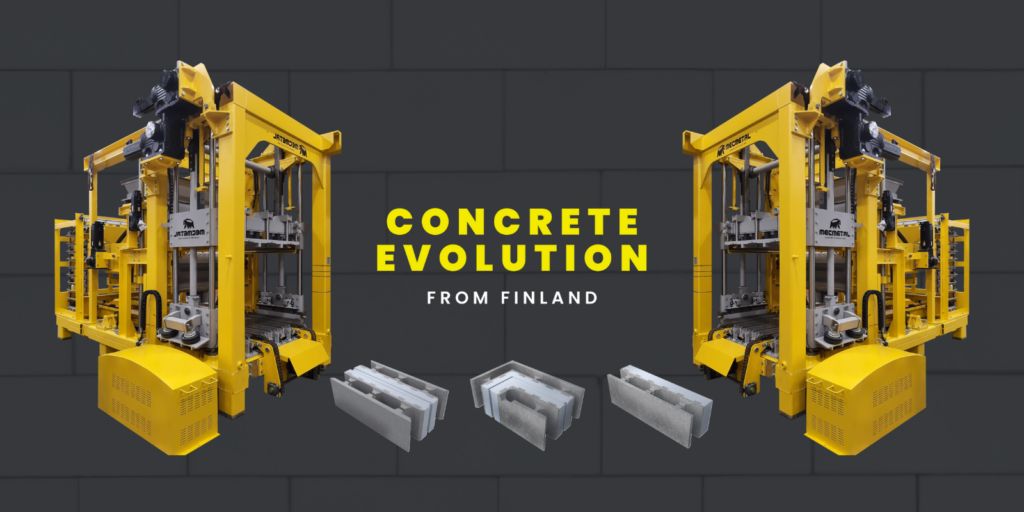

Insulated concrete block making machine

The MEC Evolution-20 block machine comes equipped with a fully automatic MEC insulation feeder and additional software installed during the manufacturing phase. The automatic insulation feed system utilizes robotic clamps and cylinders to position the insulation and feed it under the mold. The feeder also prepares and positions insulation blocks during the ongoing cycle, eliminating waiting times or stoppages. The only manual task required is to lift insulation packages from truck pallets onto the conveyor.

Concrete Intelligence and Efficiency

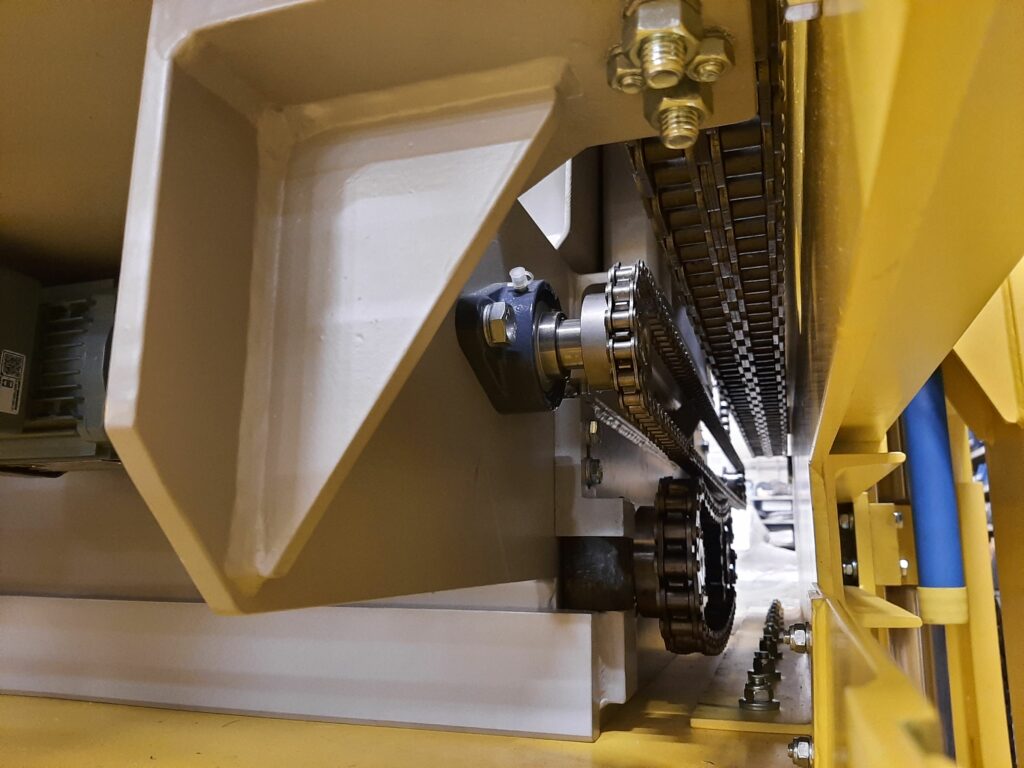

The MEC Evolution-20 block machine operates entirely on electromechanical systems and is powered by advanced, precise servo motors. The improved servo gear motor technology ensures accurate, fast movements in all conditions while significantly enhancing energy efficiency. The MEC Evolution-20 is an evolved version of its predecessor, the MEC ELECTRO.

The design of this block machine is the result of decades of experience with tested, continuously evolving mechanical solutions, as well as new innovations developed through active collaboration with customers to meet the demands of efficient production and market development.