Concrete block molds from Mecmetal, is involved in the journey of your products. From new product innovation and development to manufacturing and spare parts deliveries. Our mold making expertise and fast deliveries creates the best result, technically and financially.

What is Concrete Block Mold?

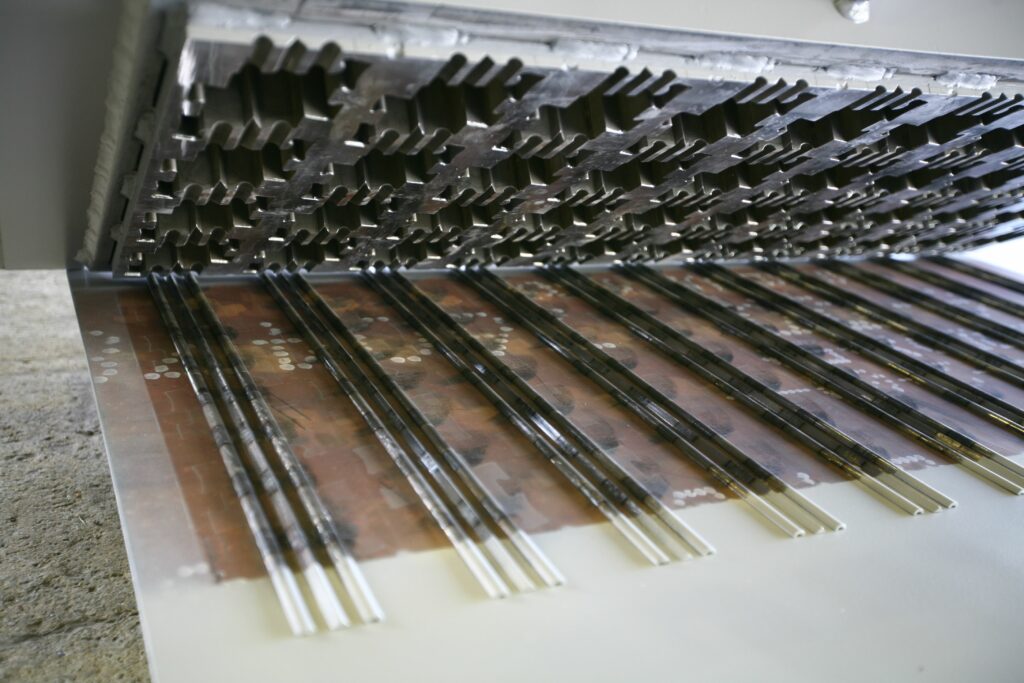

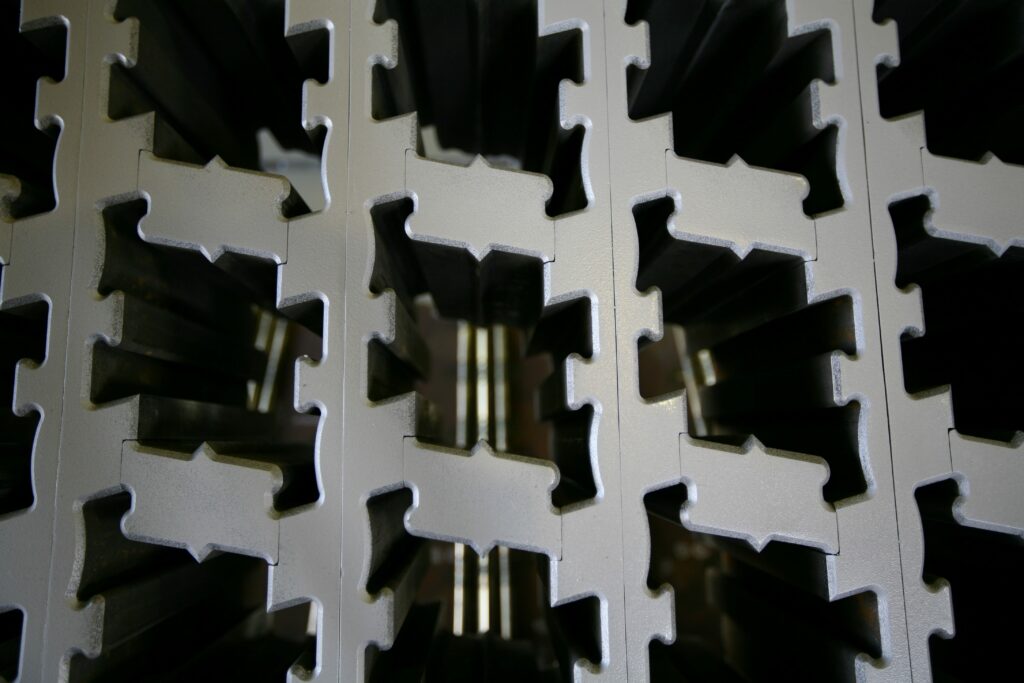

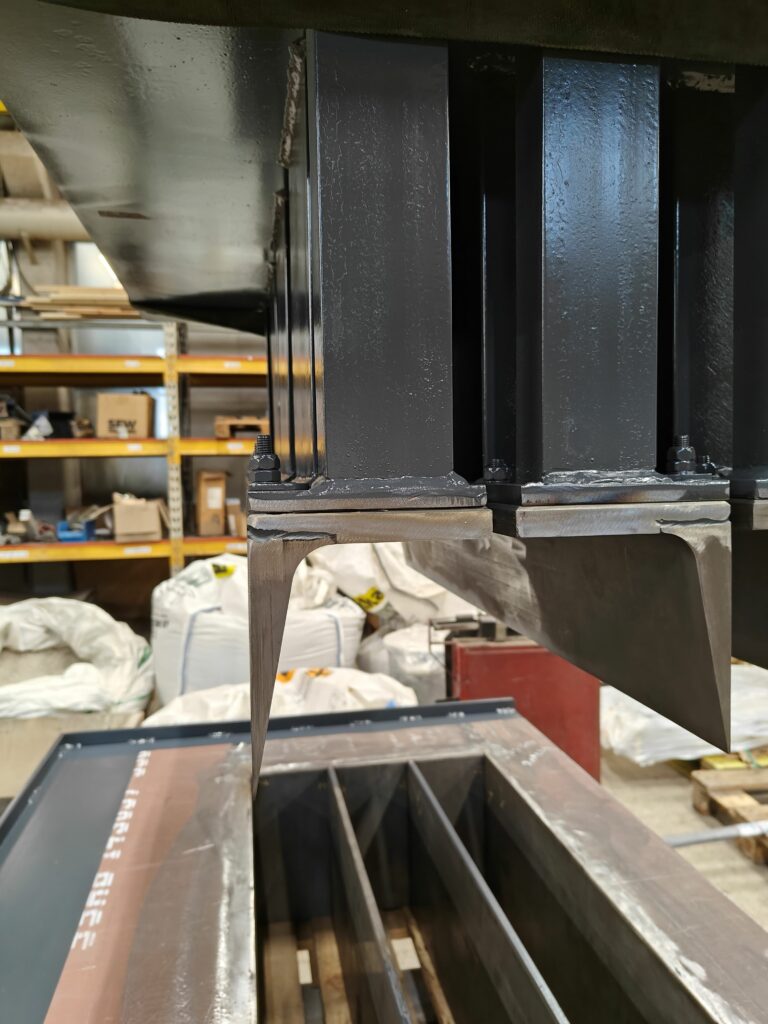

A concrete block mold for block machines is a structure used in the production of concrete blocks and pavers. It’s essentially a mold or form into which wet concrete is filled and pressed to harden, forming the desired shape of the block. These molds are typically made of different types of steel with surface treatment or other durable materials. Molds come in various sizes and shapes to produce different types of concrete blocks, such as solid blocks, cinder blocks, paver stones and curbstones. The concrete block molds play a crucial role in the manufacturing process, ensuring consistency and precision in the final product.

With MEC Molds, durability and accuracy create economy. Our molds are well know for their long life cycle and high precision. We make wearable parts changeable so molds can be used multiple times as long as main frame stays healthy. In average use, our molds runs over 100.000 production pallet cycles before wear part changes. Correctly selected materials and systematic manufacturing process of molds guarantee the right molds for the efficient and dimensionally accurate concrete block production.

We are happy to help if you are in need for new mold supplier or middle of new product innovation. Contact below our sales representative of molds, Miika and he will answer all questions and price quotes.